In 1886 the Pukekura Butter Factory, the first in the Waikato, was opened. The skimming station at Matangi supplied cream to this factory until the butter factory at Newstead was established in 1888, when supply changed there.

1894 saw the purchase of a Cheese Factory site adjacent to the railway line at Matangi by the New Zealand Packing Company. This was followed in 1900 by the opening of a Butter Factory at Matangi by the New Zealand Dairy Association (N.Z.D.A.), Mr Arthur Furze was a prime mover behind this development.

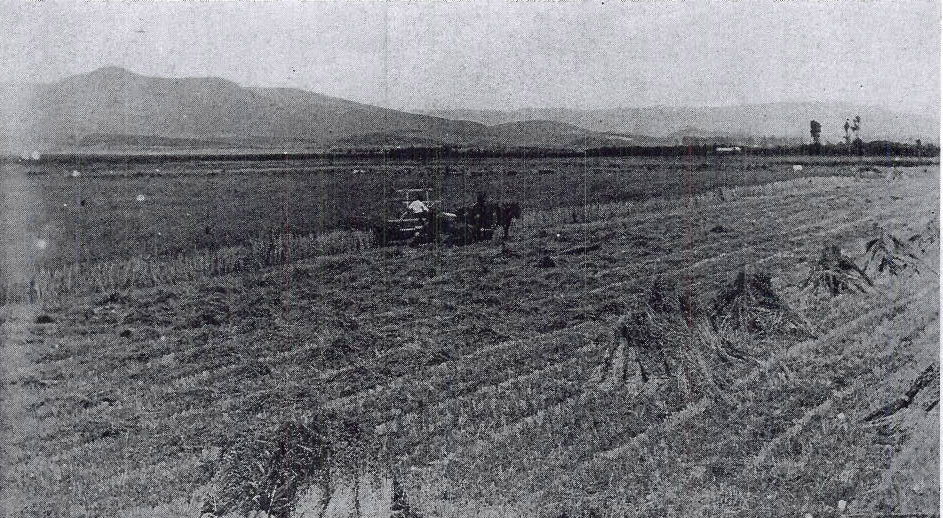

PRIOR to the opening of the dairy factories in the Waikato, farming in the district around Matangi consisted of wheat and wool production. The introduction of bumble bees into the Waikato in 1886, for the pollination of clover allowed pasture production from the rye grass/clover mix that has proved so successful in our temperate climate. In 1884 the Cambridge Railway opened up access to the Matangi district which had up till then been linked to the Waikato River for transport through the nearby Tamahere district.

Some time after 1901 W.T. Murray Limited commenced production of Highlander Condensed Milk at Matangi in the N.Z. Packing Company's building. Although 1909 saw the introduction of home separation in the Waikato, this development seems to have had little impact on Matangi where milk was usually collected whole. A fire in 1912 destroyed the Matangi creamery, but it was rebuilt soon after. In 1916 W. T. Murray Limited went into liquidation and production of condensed milk ceased. Murrays were having problems with the tin plate they were using in the canning process and a lot of milk was spoiled due to the solder on the tins not sealing properly. Their factory was taken over by the Matangi Cheese Company, who commenced cheese manufacture. This Cheese Company was a small co-operative with less than 15 suppliers. The N.Z.D.A. also built a cheese factory at Matangi in 1914 (now the Play Centre building). A typical yearly income of a small supplier at this time was one hundred and forty three pounds four shillings and five pence ($286.44) earned by J. A Thomas in the year 1917-1918.

Negotiations were concluded in 1917 by a committee of six suppliers led by Mr Lee Martin and Mr H. Pacey of the N.Z.D.A. with Joseph Nathan and Company Limited (GLAXO), resulting in the amalgamation of the various companies operating at Matangi into the N.Z. Dairy Association Group and construction of a large milk powder factory at Matangi. While construction proceeded, amalgamation with Sir William Goodfellew's Waikato Co-operative Dairy Company was arranged in 1919 to form the giant New Zealand Co-operative Dairy Company Limited (N.Z.C.D.C.).

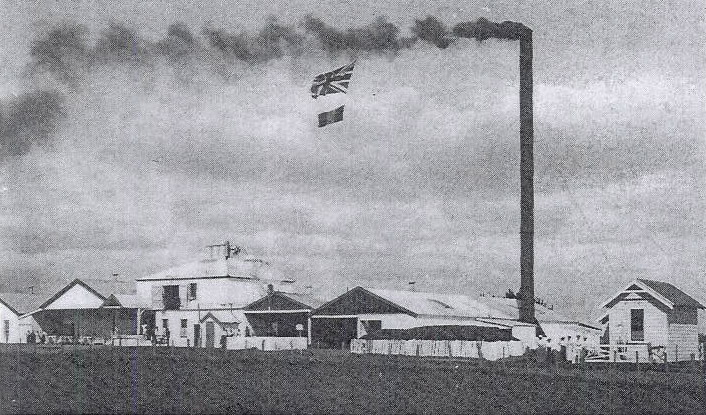

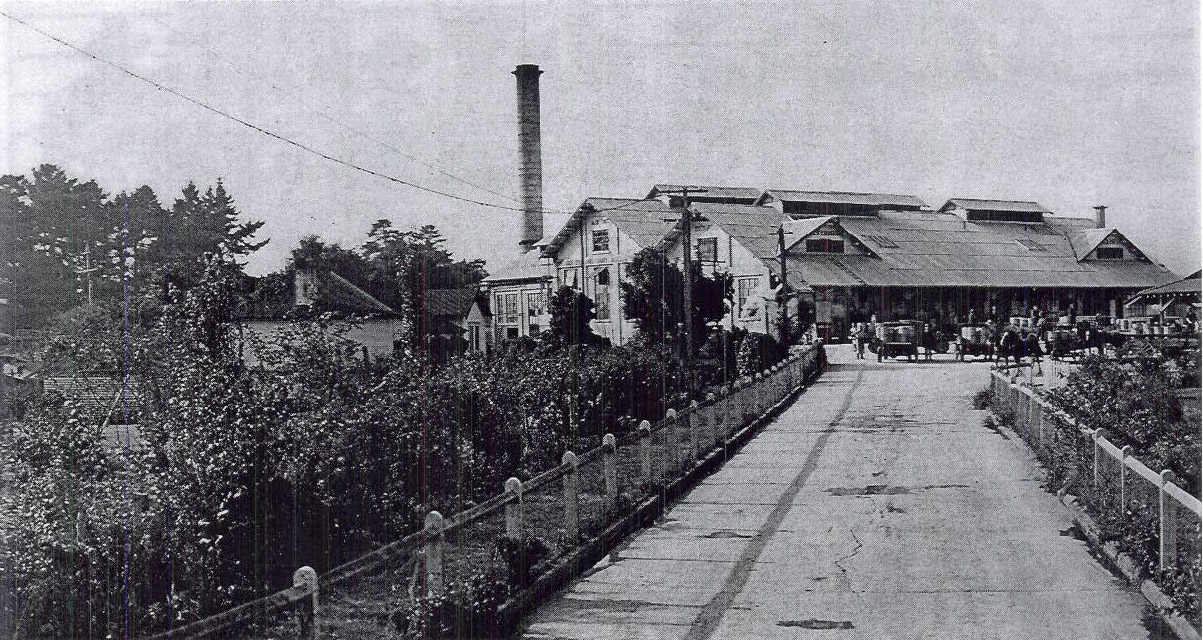

Later that year the new milk powder factory was opened by the Prime Minister, the Hon. W. F. Massey. Although the factory was owned by the N.Z.C.D.C., it was leased to Joseph Nathan and Co., for the production of Glaxo Milk Powder products. The factory and the adjacent houses were designed by the architect Mr F. C. Daniell, and built by Mr R. Sanders at a cost of forty thousand pounds. The equipment in the factory had a value of forty five thousand pounds. In association with the construction of the factory, the school, was relocated to its present site. The old Packing Company building was converted into a milk powder store, while the cheese factory building was converted into a staff hostel. Cheese manufacture ceased at this time.

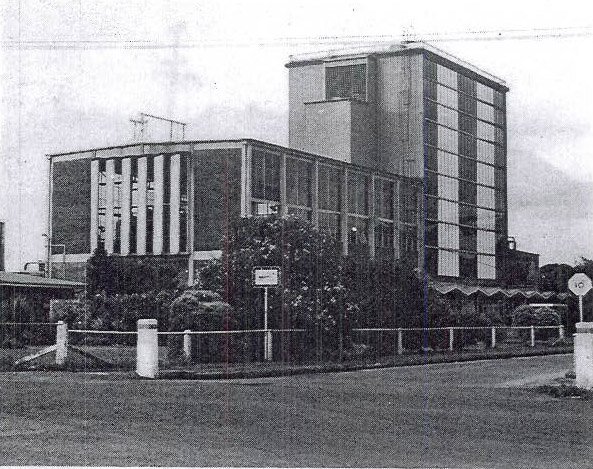

The Glaxo Factory was regarded as the model factory in the N.Z.C.D.C. group. Extensive gardens were established around the factory. All overseas visitors to the Company's Head Office in Hamilton were taken for a visit to the Glaxo Factory at Matangi.

A typical dairy farm of this period was operated by Mr Boyd who had a farm of 34 acres (13.6 hectares) on which he wintered 41 head of cattle, milked 27 cows, and had a gross return of nine hundred and eleven pounds. Cheese was again produced in 1923 after a fire burnt down part of the factory. Another fire in 1932 meant rebuilding of this factory once again. Glaxo operated at the Matangi factory until 1936 when control reverted to N.Z.C.D.C. Casein was manufactured for a short time until condensed milk manufacture recommenced.

The factory was then developed as a general purpose unit able to change output depending on the demands of the market, although the main products were milk powder and condensed milk. In 1936, 2,000 tons of condensed milk was made. Cheese was made on an as required basis. The milk supply arrived by horse and cart and motor lorry twice a day, morning and evening from the farms within a six mile (10 km) radius. During the World War II period production at Matangi turned to supporting the war effort by producing condensed milk for the U.S. Forces. A strike in 1941 by manpowered workers meant that the farmer suppliers had to work the factory at night while still farming during the day.

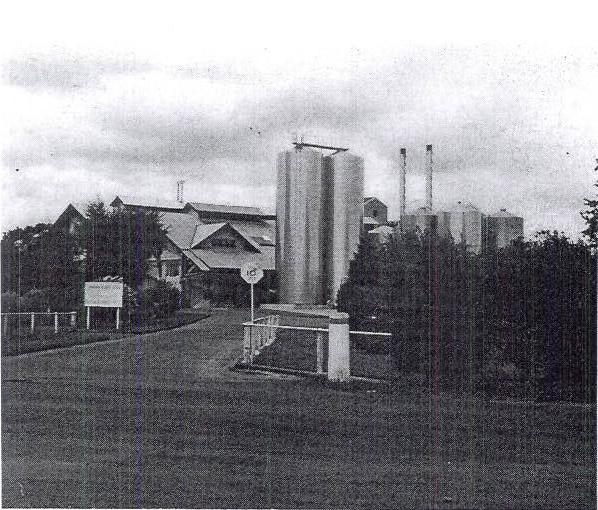

Following the war considerable investment was made in new plant at Matangi, with a humber of experiments being conducted. During 1950 and 1951 processed cheese was manufactured. At about this time the annual production of condensed milk was 20 million tons. 1954 saw the manufacture of cheese being stopped and replaced by the manufacture of casein. An experimental plant was established in 1962 to allow manufacture of skim milk and anhydrous milk fat for the production of reconstituted condensed milk in South West Asia. As the experiment was successful a full sized plant was constructed in 1965.

This manufacturing pattern continued for several years with 1974's production being 4,619 tonnes of milk powder, 2,044 tonnes of casein and 1,603 tonnes of condensed milk. By 1980 manufacture of specialty products such as canned milk shakes and canned milk puddings had been developed giving a total production of 8.5 million cans of canned products consisting mainly of condensed milk.

The development of U.H.T. technology and tetrapaks superceded canned condensed milk and in 1982 production of condensed milk ceased at Matangi. In this last season, the factory produced 2,800,000 cans of condensed milk, 272,000 tins of chocolate milk shake and 20,000 tins of strawberry milk shake.

The factory at the present time is manufacturing industrial rennet casein, one of only two factories in New Zealand doing this. This product is being used to make buttons for the high fashion Japanese market. The residual whey is being made into whey powder which is used in such things as stock food supplements and parmaceutical products. The factory also specialises in high fat baby foods and does short runs for specific customer needs. Last year and this year the Matangi factory has been fulfilling an important role in taking all milk produced out of season from as far south as Rangitaiki Plains, to as far north as Paerata and Takanini.

Of the 32 dairy farms on and around the Matangi Hamllton Road, only only, Wartle, remains. The milk tankers that supply the factory have to travel much greater distances than the 10 kilometers of 1936 to chievefficienutilisation of the milk supply. The immediate farmmg area around Matangi is now used for many horticultural purposes including the growing of peaches, maize, barley, asparagus, raspberries, boysenberries, flowers, tomatoes and grapes, together with the more traditional farming uses.